The gear lever cable is a crucial component in the operation of automotive vehicles, enabling smooth gear transitions and ensuring optimal performance. Manufactured by Chattarpati Automotive Systems based in Delhi, these automotive cables play a vital role in transmitting the driver’s gear selection to the transmission system. In this article, we will explore the significance of gear lever cables, their working principle, common issues that can arise, maintenance tips, and how to choose the right cable for your vehicle.

Introduction

Automotive vehicles rely on a complex system of mechanical and electrical components to facilitate gear changes. The gear lever cable serves as the link between the gear lever and the transmission system, allowing drivers to shift gears effortlessly. By understanding the importance of this component and how it operates, you can ensure a smooth and reliable driving experience.

Understanding Gear Lever Cable

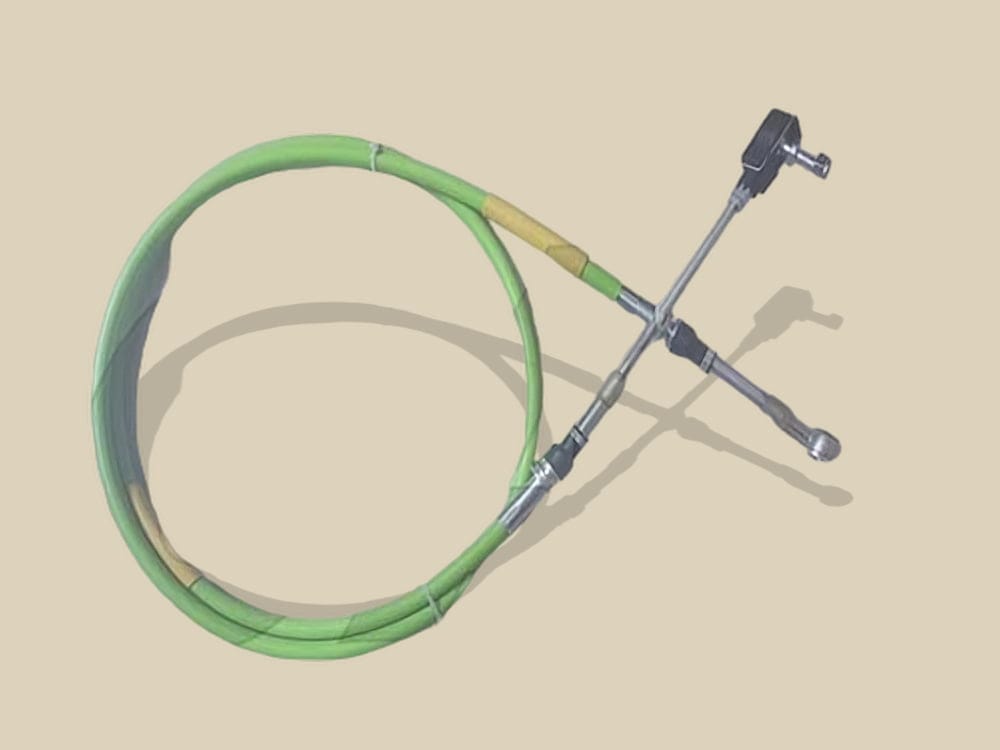

The gear lever cable is a flexible conduit that consists of an outer cable and an inner cable. These cables work together to transmit the driver’s gear selection from the gear lever to the transmission, enabling the vehicle to switch between different gears. The outer cable acts as a protective cover, shielding the inner cable from external elements and preventing damage.

Importance of Gear Lever Cable in Automotive Vehicles

Gear lever cables are essential for the proper functioning of automotive vehicles. They ensure precise gear shifts, allowing drivers to seamlessly transition between gears. Without a properly functioning gear lever cable, gear changes can become challenging, resulting in a compromised driving experience and potential damage to the transmission system.

Components of Gear Lever Cable

Outer Cable

The outer cable of the gear lever cable serves as a protective sheath. It is typically made of durable materials such as metal or high-quality plastic. The outer cable prevents the inner cable from being exposed to moisture, dirt, and other contaminants that could cause damage or hinder its performance.

Inner Cable

The inner cable is the core component of the gear lever cable. It is a flexible, sturdy wire that connects the gear lever to the transmission system. When the driver shifts gears, the movement of the gear lever is transmitted through the inner cable, engaging the desired gear in the transmission.

Working Principle of Gear Lever Cable

Shifting Gears

When the driver moves the gear lever, the motion is transferred through the gear lever cable to the transmission system. The inner cable pulls or pushes the corresponding mechanisms within the transmission, causing the gears to engage or disengage. This process allows the vehicle to switch between different gears smoothly, facilitating acceleration, deceleration, and maintaining the desired speed.

Smooth Gear Transitions

The gear lever cable’s primary function is to ensure smooth gear transitions. As the driver adjusts the gear lever, the cable transmits the precise movements to the transmission system, resulting in seamless gear changes. This enables the vehicle to operate efficiently and optimizes engine performance for various driving conditions.

Common Issues with Gear Lever Cable

Like any automotive component, gear lever cables can experience certain issues over time. It is essential to be aware of these problems to address them promptly and maintain the optimal functionality of the gear shifting system.

Cable Stretching

Over time, gear lever cables may stretch due to continuous usage. This stretching can lead to imprecise gear shifting, making it difficult to engage the desired gear accurately. If left unattended, cable stretching can worsen, affecting the overall performance of the transmission system.

Misalignment

Misalignment of the gear lever cable can occur due to various factors, such as improper installation or accidental damage. When the cable is misaligned, it can hinder the smooth movement of the inner cable, resulting in gear shifting difficulties or gear slippage. Regular inspection and realignment are necessary to prevent these issues.

Fraying or Damage

External factors, such as harsh weather conditions or physical impact, can cause fraying or damage to the gear lever cable. Frayed or damaged cables can compromise the transmission of the driver’s gear selection, leading to unreliable gear shifts or complete failure. It is crucial to inspect the cable regularly and replace any damaged sections promptly.

Signs of a Faulty Gear Lever Cable

Detecting signs of a faulty gear lever cable early on can prevent further damage and ensure a safe driving experience. Here are some common indicators that your gear lever cable may require attention:

Difficulty Shifting Gears

If you experience resistance or difficulty when shifting gears, it could indicate an issue with the gear lever cable. Stiff or unresponsive gear shifts may be a result of cable stretching, misalignment, or damage.

Gear Slippage

Gear slippage occurs when the transmission fails to hold the selected gear, causing the vehicle to unexpectedly shift into a different gear. This can be a sign of a worn-out or damaged gear lever cable that needs to be replaced.

Noisy Gear Shifts

Unusual noises, such as grinding or clicking sounds, during gear shifts can be indicative of a problem with the gear lever cable. These noises may occur due to cable fraying or misalignment, affecting the smooth engagement of gears.

Maintenance and Care Tips for Gear Lever Cable

To ensure the longevity and optimal performance of the gear lever cable, regular maintenance and care are essential. Here are some tips to keep your gear lever cable in good condition:

Regular Inspection

Periodically inspect the gear lever cable for any signs of stretching, fraying, or damage. Check the alignment and ensure that the cable is securely attached to both the gear lever and the transmission system.

Lubrication

Apply a suitable lubricant to the gear lever cable to minimize friction and promote smooth cable movement. Follow the manufacturer’s recommendations for lubrication intervals and use a lubricant specifically designed for automotive cables.

Replacing Damaged Cables

If you notice significant stretching, fraying, or damage to the gear lever cable, it is crucial to replace it promptly. Consult a professional mechanic or refer to the vehicle’s service manual for guidance on proper cable replacement procedures.

Choosing the Right Gear Lever Cable

When selecting a gear lever cable for your vehicle, several factors should be considered to ensure compatibility and optimal performance:

Quality and Durability

Choose a gear lever cable that is made of high-quality materials to ensure durability and longevity. Reliable manufacturers like Chattarpati Automotive Systems based in Delhi are known for producing high-quality automotive cables. Look for cables that are designed to withstand the rigors of daily use and offer excellent resistance to stretching, fraying, and damage.

Compatibility with Vehicle Model

Ensure that the gear lever cable you choose is compatible with your specific vehicle model. Different vehicles may have variations in cable length, attachment points, or design. Refer to the vehicle’s service manual or consult with an expert to determine the correct cable for your vehicle.

Conclusion

The gear lever cable plays a crucial role in enabling smooth gear transitions in automotive vehicles. It allows drivers to shift gears effortlessly, ensuring optimal performance and driving experience. Regular inspection, maintenance, and timely replacement of damaged cables are essential to prevent gear shifting issues and maintain the longevity of the transmission system. By choosing high-quality gear lever cables from trusted manufacturers like Chattarpati Automotive Systems, you can ensure reliable and efficient gear shifting in your vehicle. Explore our range@ https://chttarpaticables.com/gear-lever-cables/

Great information, Kudos to the author for their expertise and writing style.

Thumbs up for this well-researched and well-written piece!

I highly recommend it to anyone need to know gear lever cable in detail.

Thank you Rk